Last week, the second round of our CAD/CAM workshop took place in my small workshop in the heart of Vilsingen. Here is my brief recap of the event.

After the consistently positive feedback from last year, it quickly became clear: we absolutely have to repeat this! And to ensure that this event is just as successful as the last one, I started planning early on.

The Planning: From Idea to Clock

Together with Frieder from our marketing team, we came up with the idea of milling a clock from our key visual (the typical green annual rings that appear again and again in the tapio design). We decided to use oak wood again so that it would fit in with our previous year's project. We had already used this for our logo last year.

As we had coordinated the date for the event in good time, everyone was able to take part this time. Well. Almost everyone. Except for one colleague, whose “remote” participation we of course ensured anyway.

The Preparation

To ensure that everything runs smoothly in the evening, I first did a thorough test run in CAD/CAM. I was able to uncover a few problems with the vector file in advance and save us a lot of time in the evening. After the theoretical part, it was time to get down to business: I organized the raw material and got the machine up to speed so that everything was ready for the big show. First I had to level and sand the oak wood (or “dress” it, as the professionals say). I then calibrated the 3D probe very precisely (... my attentive colleagues really don't miss anything). So I was super prepared and could hardly wait to start the workshop!

HACK THE CNC

But before we could get started, we started on Friday morning with a small hackathon for our development team. To coincide with the workshop, my CNC was to be connected to the tapio MachineBoard by the evening. This meant that every work step could later be tracked live in the app. We had until 4 p.m. to master this challenge. We then divided up the tasks as follows:

- Noel, Simon and I took care of the values from the control software - Helmut and Moritz adapted the display template and set up the necessary users and licenses.

Shortly before the other teams and a few guests arrived, it was time for some hands-on work: we had to get a cool keg for the evening - with a moped and trailer, of course!

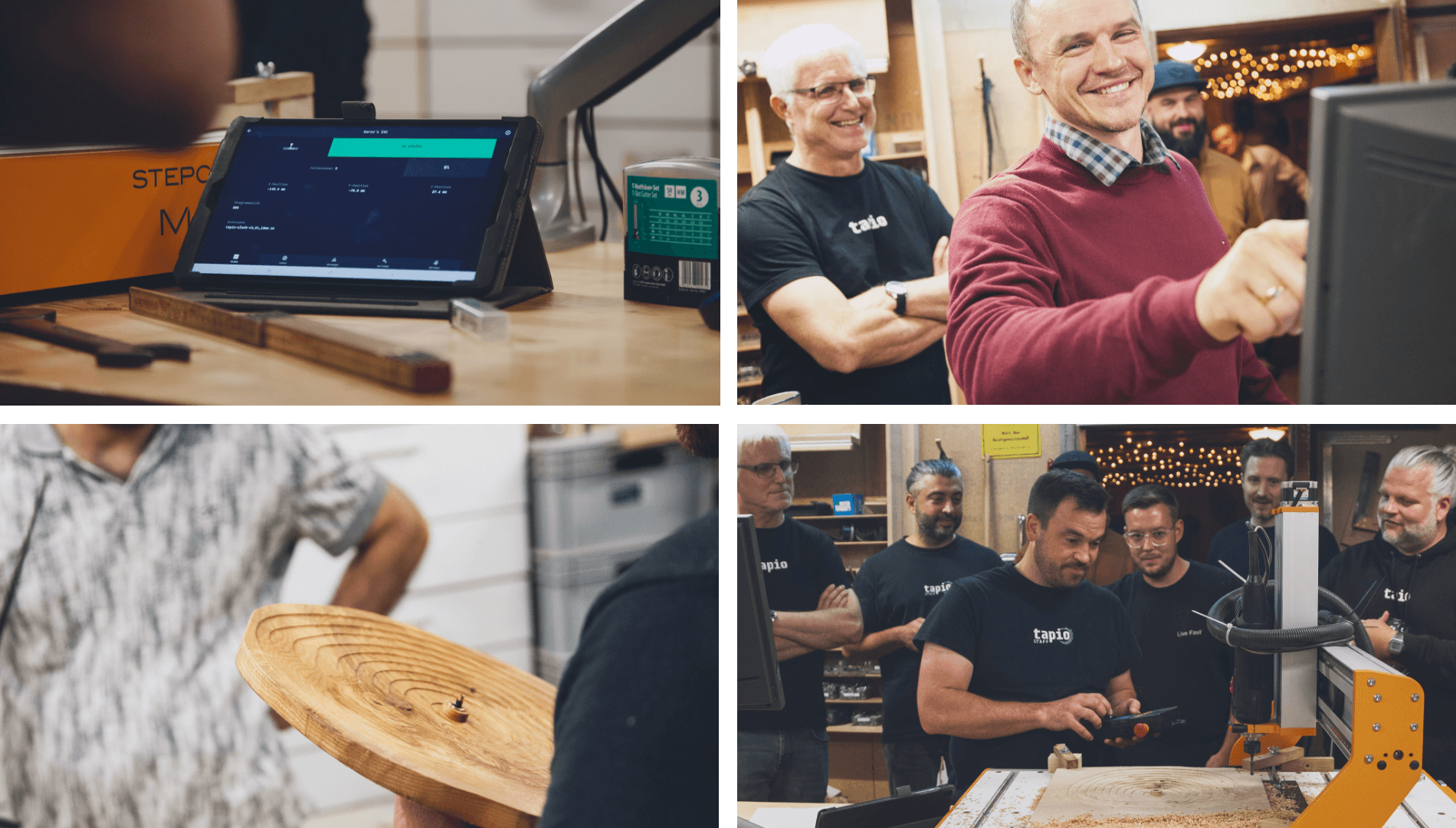

Evening Program: CAD, CAM, and CNC with tapio & Friends

In the evening, we finally kicked off the CAD/CAM workshop. At first, I was a bit nervous about whether everything would go as planned. But that quickly faded as my colleagues were super motivated and the team atmosphere was simply great. Around 5:30 PM, we started with the CAD part. Here, the team had some really helpful suggestions for improvement that we implemented right away. We quickly resolved some small CAM issues during a short snack break, allowing us to move on to the practical part at the CNC.

During the presentation of my machine, I followed the motto “Don’t dawdle, but go big!”: To epic music and light effects (thank you once again to Frieder and Moritz for the lights and sound), the marvel of engineering was rolled into the room. Afterwards, we set up the machine together, opened the MachineBoard on our smartphones, and then pressed the start button with anticipation.

As the machine started up, the status in the MachineBoard actually changed to “Am Schaffa” – an unmistakable sign that the integration my team and I had worked on all morning was successful. The effort had paid off!

Along with a few tool changes and rotating the workpiece, we, of course, also had the obligatory group photo in the “Moschtkär” (that’s “Mostkeller” in the Swabian dialect) with a little taste of this year’s cider. Thanks to colleagues Mikhail and Mohammad, I was even able to expand my country photo wall by two countries this time. We then spent the rest of the evening enjoying great conversations and watching intently as the CNC machine processed the raw material layer by layer.

The Morning After

After a long and successful evening, we took it easy on Saturday. This time we didn't have breakfast together, but we did get a lot more sleep than last year. All in all, it was another great event with even more colleagues and an even smoother process. I'm really looking forward to the next creative projects with the team in the workshop!