My smartphone has no direct connection to the machine. The machine has no WLAN. But I can see the current feed rate in the tapio MachineBoard app.

Actually, only the control of the machines knows the current speed and controls it according to the machine operator's specifications. The operator defines these at the operating unit. The control of the machine and the operating unit are directly connected and can, therefore, exchange information such as the feed rate and influence it accordingly. This fundamental principle can be found on most machines regardless of their manufacturer.

There are as many different machine manufacturers as there are different control architectures and philosophies. The question now arises of how the speed can leave this closed system without building an individual bridge for each manufacturer and possibly each control architecture.

OPC UA is available primarily for this requirement. It is a data exchange standard which is supported by all control manufacturers in one form or another. For the tapio Tech Stack, we are building on OPC UA. Our Tech Stack includes the tapio CloudConnector, the tapio technology platform (tapio core), and the tapio-based apps such as the MachineBoard.

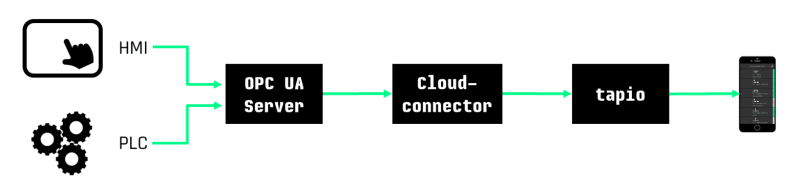

Thus now the speed comes into the app:

The machine controller measures the speed with a sensor or can read it out from the motor controller.

An OPC UA Server reads the speed from the machine controller or the user interface and presents it as an OPC UA Item.

The tapio CloudConnector reads the OPC UA item and sends the value to the tapio core via an internet connection.

The tapio MachineBoard visualizes the value in the app

In this way, further information such as machine states, process values, messages, and meter readings can be transported into the tapio ecosystem. From there, apps that have received the necessary authorizations from the customers can consume the information. The apps can originate from any app developer.

No or minimal programming effort is required to set up this connection. An OPC UA server is required to send the data on the journey. This server is often already available for current controllers or can be easily retrofitted. The second station of the data is the tapio CloudConnector, which can be installed on a Windows or Linux system. Afterward, it is only configured. The third station of the data is the tapio core. From here, the data can be displayed in the authorized apps. With these few steps, a machine can already be visualized in the tapio MachineBoard. The first connection setup for machine types that have never been connected to tapio is usually possible in one day.

At Ligna 2019 we presented systems from 14 different tapio partners live in the tapio MachineBoard.

More technical details can also be found in the blog series "Connecting the digital worlds"